Choose a test user to login and take a site tour.

4 minutes, 25 seconds

-50 Views 0 Comments 0 Likes 0 Reviews

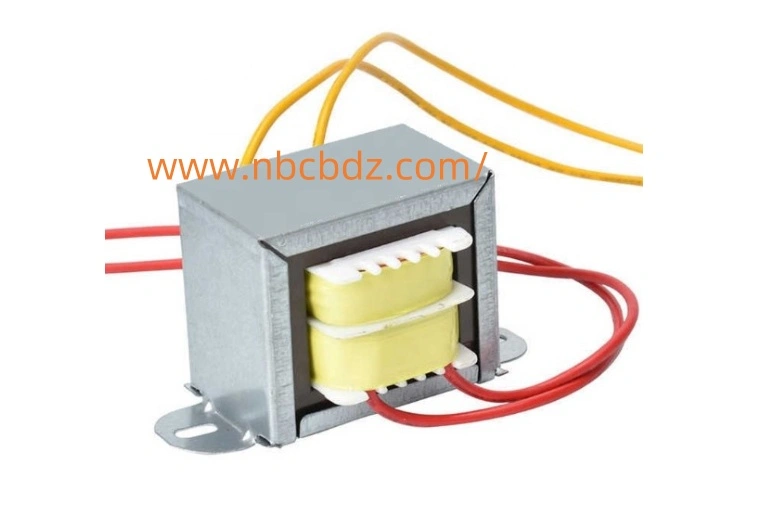

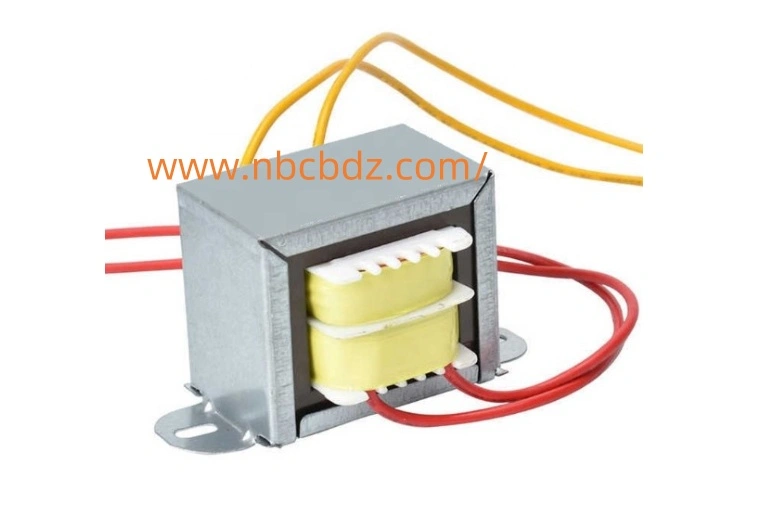

In many industrial discussions, the term EI Transformer Factory often appears beside the brand Nbcbdz as a reference point for consistent engineering methods and grounded manufacturing logic. Yet the broader meaning extends beyond a simple production site or a single name. It signals a structured approach to electrical components, one that connects design awareness with long-term operational priorities. Understanding this approach allows decision-makers to align their requirements with stable, predictable performance goals that match varied environments and usage demands.

Transformer production follows a sequence shaped by precision rather than spectacle. Every layer of core assembly, winding arrangement, and insulation behavior contributes to how a transformer withstands thermal stress and electrical fluctuations. These steps are not decorative; they are foundational. When users evaluate components, they typically consider durability, clarity of specifications, and the consistency of output under changing loads. Each of these factors is influenced directly by the manufacturing discipline that guides the transformer's creation.

The conversation around transformers also includes installation conditions. A device might appear identical on paper, yet behave differently when placed in enclosed housings, humid regions, or high-cycling systems. This is why many engineers emphasize understanding material choices, including core metals, insulation categories, and mechanical protections. The more predictable the internal structure, the easier it becomes to integrate the transformer into established power routes without unexpected deviations.

Another key consideration lies in energy flow stability. Transformers are not static objects; they respond to signals, frequencies, and patterns of demand. Their role is to maintain a balanced exchange between voltage levels, reducing strain on connected circuits and supporting safe operation. To achieve this balance, coil uniformity and core alignment must follow verified arrangements instead of improvised shortcuts. These are the details that silently shape the everyday usefulness of a transformer.

Beyond structural aspects, responsible transformer planning involves assessing lifecycle expectations. Components that operate for long durations face gradual thermal variation, vibration influence, and insulation aging. A carefully produced transformer accounts for these realities from the start. It is designed with predictable margins and repeatable behaviors, minimizing the chance of abrupt failures that could interrupt broader systems. This form of reliability is not the result of dramatic claims; it is the accumulation of methodical decisions carried out during production.

A related subject is adaptability. Power systems change across industries, from compact equipment to large-scale installations. Transformers must maintain clarity of function while fitting into distinct layouts. Compatibility does not require unnecessary complexity; instead, it relies on proportional design, straightforward mounting, and dependable electrical behavior. By keeping the structural choices transparent, manufacturers allow engineers to plan confidently without needing speculative assumptions.

Finally, responsible sourcing and usage benefit from understanding how production philosophies influence applied performance. Selecting a transformer is not merely a transaction but an alignment of expectations. When buyers examine construction habits, material consistency, and operational reasoning, they enable their systems to run with fewer uncertainties and clearer maintenance paths. This practical awareness supports smoother workflows and strengthens long-term project value.

If you want a closer look at the craftsmanship principles and production logic behind modern transformers, a visit to https://www.nbcbdz.com/product/ ,may reveal details that reshape how you evaluate your next component choice.

Share this page with your family and friends.